- Description

- How to Use

- FAQs and Tips

- How to Order

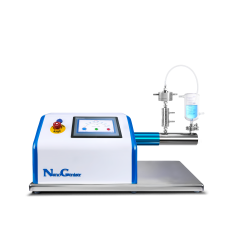

UltraGenizer High Shear Homogenizer:

UltraGenizer is a laboratory ultra high pressure processing device. It is an electrically-driven and bench-top high shear homogenizer, which requires no compressed air or hydraulic oil to achieve maximum 4,200 bar (60,000 psi) operating pressure.

Application of UltraGenizer High Shear Homogenizer:

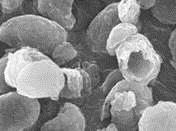

Nano emulsions

Nano dispersions

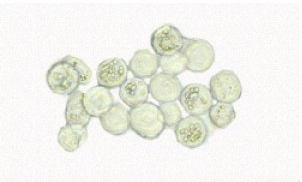

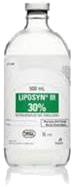

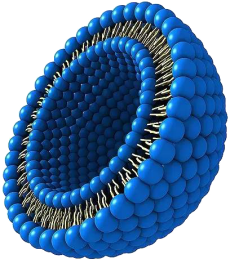

Liposomes

Nanoparticles

Graphene

Deagglomeration

Nano dispersions

Liposomes

Nanoparticles

Graphene

Deagglomeration

Performance of UltraGenizer High Shear Homogenizer:

Energy efficient, 1/2 energy loss of the most homogenizers

Small (integrated design delivers the light weight and small dimensions)

Smart (programming control systems confer diligent functions: controlled inlet volume ± 0.1mL; auto stop with time/volume)

Silent (noiseless performance)

Strong (more than 150 mL/min at 60,000 psi)

CE compliant and RoHS compliant

Small (integrated design delivers the light weight and small dimensions)

Smart (programming control systems confer diligent functions: controlled inlet volume ± 0.1mL; auto stop with time/volume)

Silent (noiseless performance)

Strong (more than 150 mL/min at 60,000 psi)

CE compliant and RoHS compliant

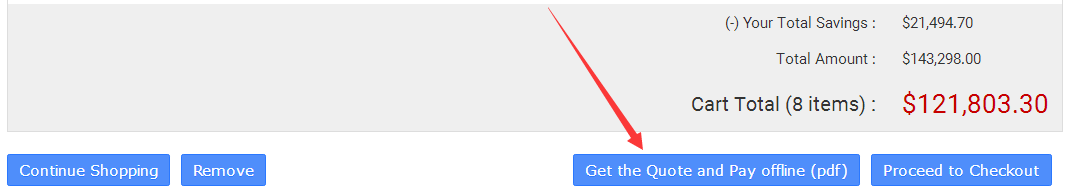

| Specifications | ||||||

| Catalog No. | UG-20K UG-25K UG-30K UG-40K UG-45K UG-60K | |||||

| Flow Rate | 35L/hr 30L/hr 25L/hr 20L/hr 15L/hr 12L/hr | |||||

| Min. Sample | 30mL 25mL 25mL 20mL 20mL 15mL | |||||

| Max. Pressure | 20,000psi 25,000psi 30,000psi 40,000psi 45,000psi 60,000psi | |||||

| Dimensions(cm) | 150 × 68 × 48 | |||||

| Weight | ~200 kg | |||||

| Max. Temp. | 70ºC (158ºF) | |||||

| Power | 380V | |||||

| Cleaning | Flush to clean | |||||

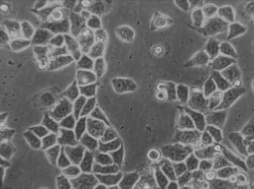

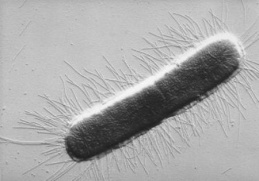

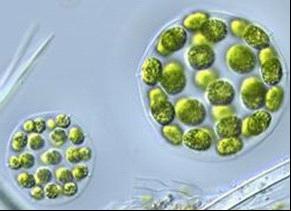

| Application | Nano emulsion, fat emulsion, liposome, cell disruption, nano dispersion, de-agglomeration, nanoparticle, graphene | |||||

| Features | Digital display of pressure or pressure gauge | |||||

| Standard Features | ||||||

| Parts | Ultra Y-type diamond interaction chamber with cooling option | |||||

| Control System | High pressure programming control systems: touch screen, speed control, auto stop control by volume, time, pressure or temperature, settable volume control as low as 1mL, display of flow rate and time, overload protection | |||||

| Pressure Gauge | Digital display on the touch screen | |||||

| Inlet Type | 3/8" HP coupling | |||||

| Outlet Type | 3/8" HP coupling | |||||

| Inlet Reservoir | 100mL syringe | |||||

| Outlet Reservoir | 100mL syringe | |||||

| Product Material | 316L stainless steel, tungsten carbide, viton, teflon | |||||

| Material Standard | Sanitary grade, FDA, GMP | |||||

| Warranty | 1 year against any manufacturing defects | |||||

| Option Features | ||||||

| Parts | High pressure extruders, homogenizing valves, heat exchanger | |||||

| Control System | Mechanical control: speed, start, stop control | |||||

| Detector | Pressure gauge, pressure transducer up to 8 optional, temperature transducer up to 8 optional | |||||

| Outlet Type | Tri-clamp or luer | |||||

| Heat Exchanger | HPE-100-3D; HPE-150-3D; HPE-200-3D | |||||

| Liposome Extruder | GOE-200mL; GOE-1000mL | |||||

| Inlet Reservoir | 10mL, 20mL, 50mL, 100mL, 200mL, 500mL syringes, S/S cylinder, jacketed glass cylinder or online | |||||

| Outlet Reservoir | 10mL, 20mL, 50mL, 100mL, 200mL, 500mL syringe, S/S cylinder, jacketed glass cylinder or online | |||||

| Cylinder | Titanium high pressure cylinder (resistant to strong acid and base) | |||||

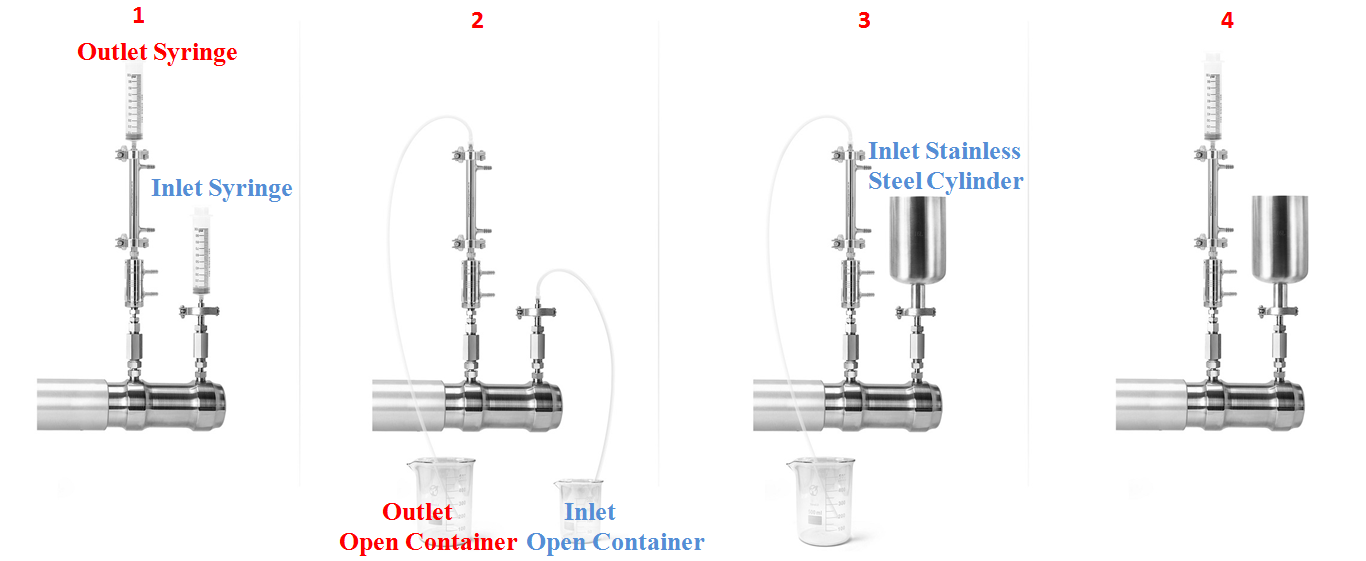

Varieties of Inlet and Outlet for UltraGenizer

Inlet: syringe; open container; stainless steel cylinder

Outlet: syringe; open container; stainless steel cylinder

Outlet: syringe; open container; stainless steel cylinder

USD

USD

949-932-0294 Los Angeles

949-932-0294 Los Angeles  Nano@Genizer.com

Nano@Genizer.com