The NanoGenizer | A High-Pressure Homogenizer for Laboratory Settings

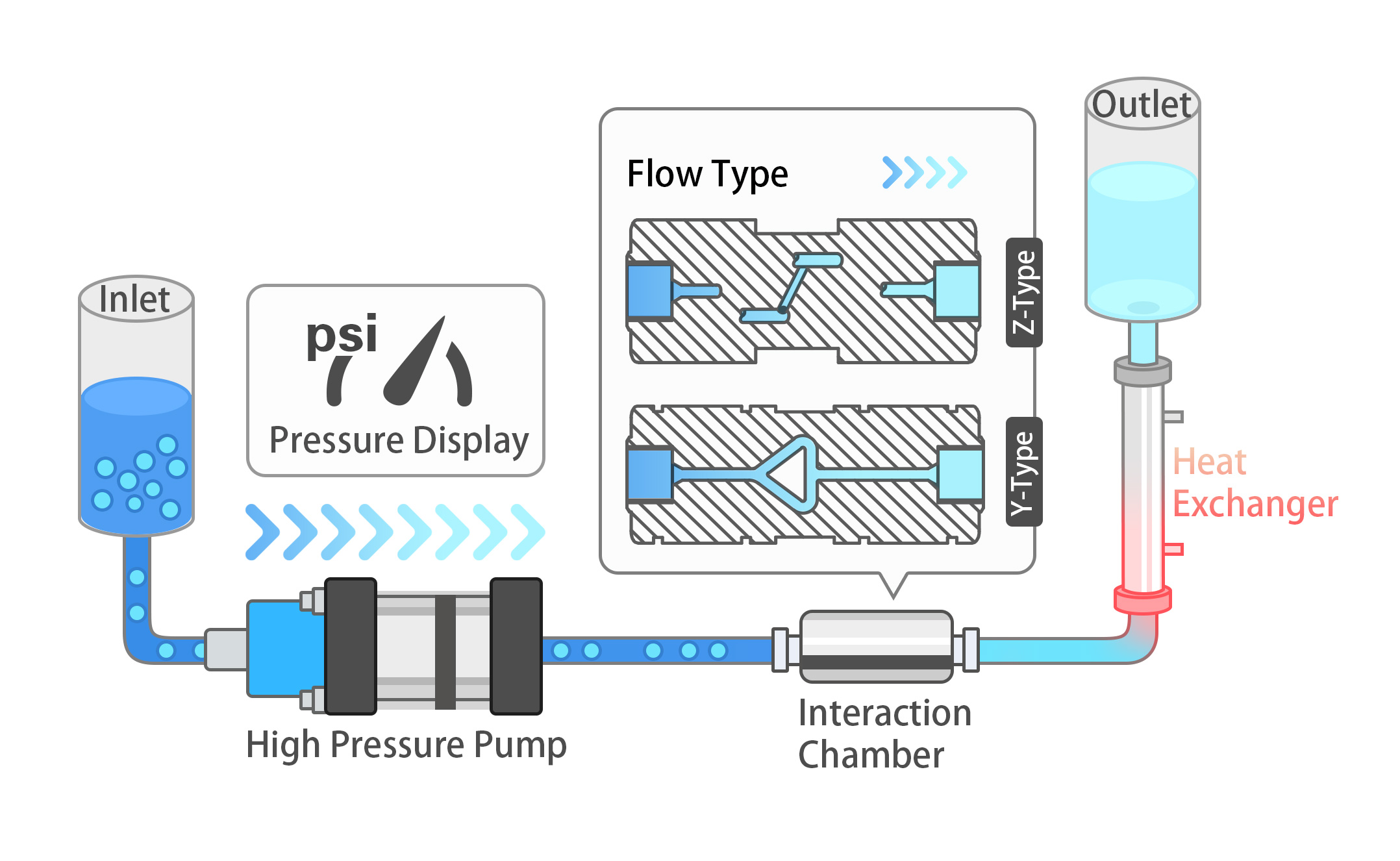

The NanoGenizer is the most popular unit from Genizer. This high-pressure homogenizer is perfect for laboratory settings because of its compact and energy efficient design. The NanoGenizer is simple to use. It plugs into the wall and has a convenient touch screen with an auto-stop function. The body of the NanoGenizer serves as the engine to power the ceramic piston. The sample travels in through the inlet valve and out the outlet valve into the diamond interaction chamber (DIXC).

The NanoGenizer is the most popular unit from Genizer. This high-pressure homogenizer is perfect for laboratory settings because of its compact and energy efficient design. The NanoGenizer is simple to use. It plugs into the wall and has a convenient touch screen with an auto-stop function. The body of the NanoGenizer serves as the engine to power the ceramic piston. The sample travels in through the inlet valve and out the outlet valve into the diamond interaction chamber (DIXC).

The DIXC can be either Y-shaped or Z-shaped. In the Y-shaped interaction chamber, the sample separates into two streams. The streams turn at a 90° angle and collide with each other. Where the two streams collide, forces like high shear and cavitation homogenize the sample. While in the Y-shaped interaction chamber the sample collides with itself, in the Z-shaped chamber the sample collides with the wall of the chamber.

In addition to the cooling function in the interaction chambers, Genizer offers a real-time cooling system, with the heat exchanger. This feature is useful for thermally unstable samples. Common applications for the NanoGenizer include but are not limited to nanoemulsions, cell disruption and deagglomeration.

USD

USD 949-932-0294 Los Angeles

949-932-0294 Los Angeles  Nano@Genizer.com

Nano@Genizer.com